Power semiconductors are the core of electrical energy conversion and Circuit control in electronic devices. They are mainly used to change voltage and frequency, DC and AC conversion in electronic devices, and are the core of electrical energy conversion and circuit control in electronic devices.

There are many types of power semiconductor devices, which can be divided into three categories: power IC, power module and power discrete device according to the degree of integration. Among the power discrete devices, MOSFET, power diode, and IGBT are the most important categories.

According to iHS forecasts, MOSFETs and IGBTs will be the semiconductor power devices with the strongest growth in 2020-2025. The market space for growth was disassembled by industry experts into two aspects: replacement markets brought about by depreciation and new markets brought about by the deepening of electrification. Since the new market stems from the deepening of electrification, the most intuitive downstream industry that can have a greater impact on the scale of the power semiconductor market is the electric vehicle industry. The basis for this judgment is mainly derived from the increase in the amount of automotive semiconductors that has more than doubled as the degree of electrification deepens. According to strategic analysis data, the amount of semiconductors used in traditional fuel vehicles is US$338 per vehicle, and the amount of semiconductors used in electric vehicles has reached US$704, an increase of 108%. The newly added semiconductor consumption of electric vehicles is concentrated on power device products, and a single car will increase the consumption of power devices by US$282. The semiconductor consumption of power devices in a single vehicle has increased from 21% of gasoline vehicles to 55% of electric vehicles.The increased amount is mainly reflected in two aspects. One is the new application of a large number of power devices in the motor control system; the other is the new demand for a large number of power devices in charging piles and car chargers.

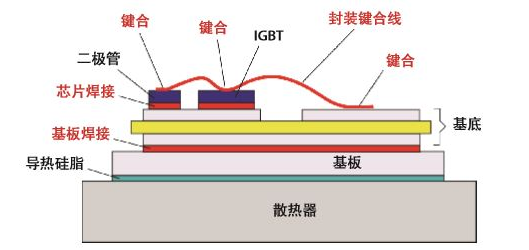

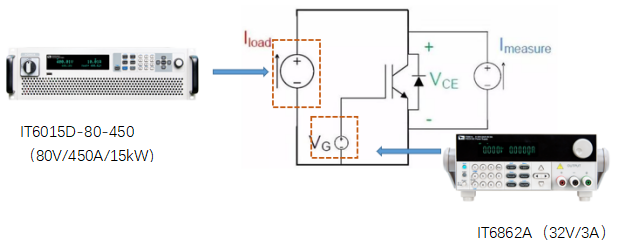

Let’s take electric vehicles as an example to introduce ITECH’s high-power IGBT module test solutions for electric vehicles. The following is an IGBT module for passenger car motor controllers (see Figure 1 for specifications). We know that IGBT module power cycle test is an important item for the life assessment of mechanical connections. Here, the customer needs to age 6 IGBT Modules at the same time. Power cycling Iload circuit constant current source must meet: 30V/400A/12kW

IGBT side screenshot

Power cycle test

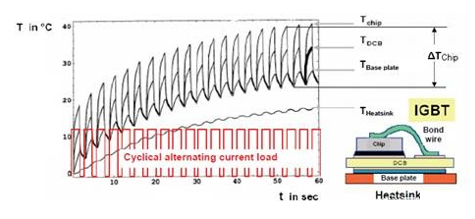

Note: Power cycling, as the name implies, is to allow the chip to intermittently flow current to generate gap heating power, thereby causing the chip temperature to fluctuate. Because the heat source generates heat from the chip itself, it is generally called active heating. The period of the power cycle is generally 3 to 5 seconds.Through the power cycle test, it can be checked whether the IGBT module will fall off due to heat, break the bonding wire, or the chip solder layer will be separated within the specified number of lifespans.

ITECH’s solution:

According to standard requirements, a constant current Iload is applied to the IGBT module under test during a power cycle. When the junction temperature Tj rises to Tjmax, the output is turned off; when the junction temperature drops to Tjmin, the output is turned on again. In this cycle, it is detected whether the IGBT module has failed.

Since the on-off of the IGBT main circuit is controlled by the gate voltage VG, the VG power supply here provides a constant 30V voltage. When the main circuit of the power tube needs to be turned off, the driving voltage is disabled by turning off the VG power supply. The loop is shut down.According to customer needs, we provide constant Iload current for IGBT module aging through IT6015D-80-450, and use IT6862A to provide 30V enable voltage for the gate. The advantage of this solution is that customers have system requirements, provided by ITECH In addition to meeting the customer’s parameter requirements, the 15KW power supply has a high power density of 3U to meet the needs of highly integrated systems; in addition, the IT6862A high-precision linear power supply meets the needs of users with high precision and low power consumption.

IGBT accounts for a very large proportion of electric vehicles. Among them, 30% of the raw material cost of the DC charging pile is IGBT, which accounts for about half of the cost of the motor drive system, and the motor drive system accounts for 15-20% of the total vehicle cost, that is to say, IGBT It accounts for 7-10% of the cost of the entire vehicle. It is the second most expensive component besides the battery, and it also determines the energy efficiency of the entire vehicle. In most cases, IGBT is used as a switch. In short, the switch is used to control the conduction and cut-off of the current. The electrical performance parameters of the switching device are tested, such as: breakdown voltage, open state Current, quiescent current, threshold or cut-off voltage, etc., must be carried out in the corresponding circuit, and the simplest and most direct way to form a circuit is through the power supply and the load. As a professional power supply and load manufacturer, ITECH has the highest product voltage. Up to 2250V, current up to 2500A, power up to 1152KW, up to 700+ stand-alone models, which can cover most of the IGBT specifications on the market, whether you are testing as a stand-alone machine or for system integration, we can Provide a complete test solution.