“In the manufacturing process of integrated Circuits, there is an important link – lithography. It is because of it that we can realize functions on tiny chips. Modern scribing technology can be traced back to 190 years ago. In 1822, Frenchman Nicephore niepce began to try to replicate an imprint (pattern) etched on oil paper after light experiments with various materials. He put oil paper on a piece of glass, The slides were coated with pitch dissolved in vegetable oil. After 2 or 3 hours of sun exposure, the asphalt in the light-transmitting part becomes obviously hard, while the asphalt in the opaque part is still soft and can be washed off by the mixture of rosin and vegetable oil. By etching the glass plate with strong acid,

“

In the manufacturing process of integrated circuits, there is an important link – lithography. It is because of it that we can realize functions on tiny chips. Modern scribing technology can be traced back to 190 years ago. In 1822, Frenchman Nicephore niepce began to try to replicate an imprint (pattern) etched on oil paper after light experiments with various materials. He put oil paper on a piece of glass, The slides were coated with pitch dissolved in vegetable oil. After 2 or 3 hours of sun exposure, the asphalt in the light-transmitting part becomes obviously hard, while the asphalt in the opaque part is still soft and can be washed off by the mixture of rosin and vegetable oil. By etching glass plates with strong acid, Niepce produced a replica of the engraving of Bishop d’Amboise in 1827.

More than 100 years after the invention of Niepce, during World War II, it was first used to make printed Circuit boards, that is, to make copper circuits on plastic boards. By 1961, photolithography was used to fabricate a large number of tiny transistors on Si, with a resolution of 5um at that time. Now, in addition to visible light lithography, higher resolution methods such as X-ray and charged particle scribing have emerged.

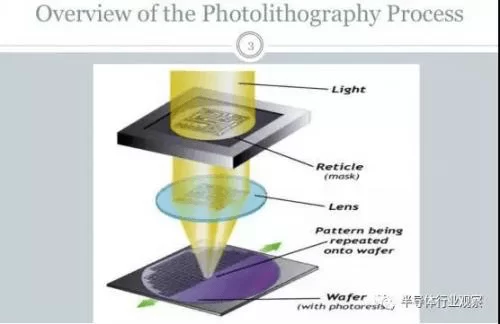

The so-called photolithography, according to the definition of Wikipedia, is an important step in the semiconductor device manufacturing process. The graphics are transferred to the substrate where they are located. The substrate mentioned here not only includes silicon wafers, but also other metal layers and dielectric layers, such as glass and sapphire in SOS.

The basic principle of lithography is to use the characteristics of photoresist (or photoresist) to form corrosion resistance due to photochemical reaction after being exposed to light, and to engrave the pattern on the mask onto the processed surface.

Lithography Principle Intention

Lithography is not a simple process, it goes through many steps:

photolithography process

Now let’s introduce the photolithography process in detail:

1. Wafer Clean

The purpose of cleaning the wafer is to remove contaminants, remove particles, reduce pinholes and other defects, and improve photoresist adhesion

Basic steps: chemical cleaning – rinsing – drying.

After the silicon wafer has been processed by different processes, its surface has been seriously contaminated. Generally speaking, the surface contamination of the silicon wafer can be roughly divided into three categories:

A. Contamination by organic impurities: It can be removed by the dissolution of organic reagents combined with ultrasonic cleaning technology.

remove.

B. Particle contamination: Mechanical scrubbing or ultrasonic cleaning technology can be used to remove particles with a particle size of ≥ 0.4 μm, and megasonic waves can be used to remove particles of ≥ 0.2 μm.

C. Metal ion contamination: chemical methods must be used to clean the contamination. There are two types of metal impurity contamination on the surface of silicon wafers:

a. One is that contaminant ions or atoms are attached to the surface of the silicon wafer by adsorption and dispersion.

b. The other type is that the positively charged metal ions get electrons and then attach (eg “electroplating”) to the surface of the silicon wafer.

The purpose of chemical cleaning of silicon polishing wafers is to remove this kind of contamination. Generally, the following methods can be used to remove the contamination.

a. Use a strong oxidant to “electroplate” the metal ions attached to the silicon surface, oxidize them to metal, dissolve in the cleaning solution or adsorb on the surface of the silicon wafer.

b. Use harmless small-diameter strong positive ions (such as H+) to replace the metal ions adsorbed on the surface of the silicon wafer to dissolve them in the cleaning solution.

c. Ultrasonic cleaning with plenty of deionized water to remove metal ions from the solution.

The immersion RCA chemical cleaning process proposed by the RCA laboratory in the United States has been widely used since 1970. In 1978, the RCA laboratory introduced the megasonic cleaning process. In recent years, various cleaning technologies based on the RCA cleaning theory have been continuously developed. For example: the centrifugal spray chemical cleaning technology launched by the US FSI company, the closed overflow cleaning technology of the Full-Flow systems launched by the former US CFM company, the chemical cleaning technology between the immersion and the closed type launched by the US VERTEQ company (eg Goldfinger Mach2 cleaning system), double-sided Sassafras cleaning technology (eg M3304 DSS cleaning system) of SSEC Corporation of the United States, and Japan’s chemical-free dielectric ionized water cleaning technology (cleaning with dielectric ultrapure ionized water) makes the polished sheet Surface cleaning technology has reached a new level, HF / O3 based chemical cleaning technology for silicon wafers.

2. Pre-bake and Primer Vapor

Since the photoresist contains a solvent, it needs to be about 80 degrees for the silicon wafer coated with the photoresist. The wafer dehydration bake removes moisture from the wafer surface and enhances the adhesion of the photoresist to the surface, typically around 100 °C. This is done in conjunction with primer coating.

Primer coating enhances the adhesion of the photoresist (PR) to the wafer surface. Widely used: (HMDS) Hexamethyldisilazane, HMDS vapor coating prior to PR spin coating, wafer cooling with cooling plate prior to PR coating.

Prebake and Primer Vapor Coating

3. Photoresist Coating

The usual steps for photoresist coating are wet oxidation at 900-1100 degrees before photoresist coating. The oxide layer can be used as a stencil for wet etching or B implantation. As the first step of the photolithography process itself, a thin layer of organic polymer compound sensitive to ultraviolet light, commonly known as photoresist, is to be coated on the surface of the sample (SiO2). First, the photoresist is taken out of the container and applied to the surface of the sample placed in the glue coating machine, (the sample is fixed on the sample stage by vacuum negative pressure), and then the sample is rotated at high speed, and the speed is determined by the viscosity of the glue and the thickness of the desired glue Sure. At such high speeds, the glue flows toward the edge under the action of centrifugal force.

The gluing process is the first and most important step in the pattern conversion process. The quality of the paste directly affects the defect density of the processed device. In order to ensure the repeatability of the line width and the subsequent development time, the thickness uniformity of the same sample and the thickness consistency between different samples should not exceed ±5nm (±0.3% for 1.5um thickness).

The determination of the target thickness of the photoresist mainly considers the chemical properties of the photoresist itself and the fineness of the lines and gaps in the pattern to be reproduced. Too thick glue will result in edge coverage or connectivity, hillock or field-like glue appearance, and reduced yield. In MEMS, the glue thickness (after baking) is between 0.5-2um, while for special microstructure fabrication, the glue thickness is sometimes on the order of 1 cm. In the latter, spin coating will be replaced by methods such as cast glue or plasma glue polymerization. The optimization of the conventional photoresist coating process needs to consider the dispensing speed, dispensing amount, rotation speed, ambient temperature and humidity, etc. The stability of these factors is very important.

Let me say here that the main components of photoresist are a polymer (resin), a sensitizer and a solvent. The polymer changes its structure when irradiated, the solvent enables it to be spun off and forms a film on the surface of the sample, and the sensitizer controls the chemical reaction of the polymeric phase. Photoresists without sensitizers are sometimes called unitary or unary systems, while those with sensitizers are called binary systems. Solvents or other additives are usually not counted in the arity because they do not directly participate in the photochemical reaction of the photoresist.

According to the different properties, photoresists can be divided into positive and negative photoresist.

In the early stage of process development, negative glue has always dominated the photolithography process. With the emergence of VLSI IC and 2-5 micron pattern size, negative glue can no longer meet the requirements. Then came the positive glue, but the disadvantage of the positive glue is the poor bonding ability.

Using positive glue requires changing the polarity of the mask, which is not a simple pattern flip. Because the mask is combined with two different photoresists, the size obtained by photolithography on the surface of the wafer is different. Due to the diffraction effect of light around the pattern, the combination of negative photoresist and bright field mask is used in the photoresist. The size of the pattern obtained on the resist layer is smaller than that on the mask. Using a combination of positive photoresist and a darkfield mask will increase the size of the features on the photoresist layer.

photoresist coating

4. Soft Bake

After the photoresist is applied, a soft drying operation is required, which is also called pre-baking. The pre-baking can evaporate the solvent in the photoresist and make the coated photoresist thinner.

In the liquid photoresist, the solvent component accounts for 65%-85%. Although the liquid photoresist has become a solid film after the sling, it still contains 10%-30% of the solvent, which is easy to contaminate dust. By baking at a higher temperature, the solvent can be volatilized from the photoresist (the solvent content is reduced to about 5% after the pre-baking), thereby reducing the contamination of dust. At the same time, this step can also relieve the film stress caused by the high-speed rotation, thereby improving the adhesion on the photoresist substrate.

During the pre-baking process, due to the volatilization of the solvent, the thickness of the photoresist will also be reduced, generally by about 10%-20%.

Baking Systems

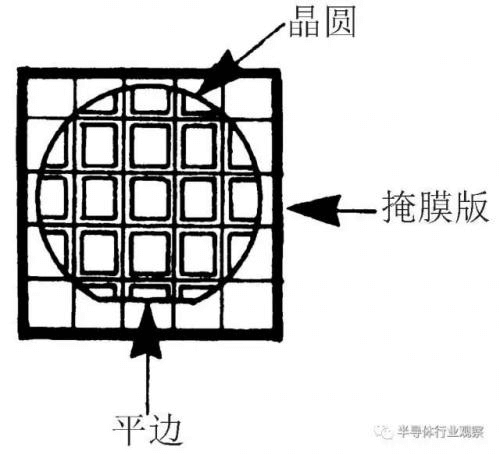

4. Alignment

The lithography alignment technology is an important step before exposure as one of the three core technologies of lithography. Generally, the alignment accuracy is required to be 1/7-1/10 of the thinnest line width size. With the improvement of lithography resolution, the requirements for alignment accuracy are also getting higher and higher. For example, for a line width of 45am, the alignment accuracy is required to be around 5am.

Alignment technology has also undergone rapid and diverse development, driven by improved lithography resolution. From the principle of alignment and the classification of mark structures, the alignment technology has ranged from the geometric imaging alignment method in the early projection lithography, including video image alignment, binocular microscope alignment, etc., to the later zone plate alignment method , Interference Intensity Alignment, Laser Heterodyne Interference and Moiré Alignment. From the alignment signal, it mainly includes the alignment of the microscopic image of the mark, the alignment based on the light intensity information and the alignment based on the phase information.

The alignment rule is that the first lithography just aligns the Y-axis on the reticle at 90º with the flat edge on the wafer, as shown. Subsequent masks are aligned with the previous mask with the pattern using alignment marks. The alignment mark is a special pattern (see picture) that is distributed along the edge of each chip pattern. After the photolithography process, the alignment marks remain on the surface of the chip forever and are used as the next alignment.

Alignment methods include:

a. Pre-alignment, automatic laser alignment through notch or flat on the silicon wafer

b. Through the alignment mark, it is located on the cutting groove. In addition, the interlayer alignment, that is, the overlay accuracy, ensures the alignment between the pattern and the pattern that already exists on the silicon wafer.

5. Exposure

In this step, the photoresist covering the substrate is selectively illuminated with light of a specific wavelength. The photosensitive agent in the photoresist will undergo a photochemical reaction, so that the chemical composition of the irradiated area (photosensitive area) of the positive photoresist and the unirradiated area of the negative photoresist (non-photosensitive area) will change. These chemically changed areas can be dissolved in a specific developer in the next step.

After receiving light, the sensitizer DQ in the positive photoresist will undergo a photochemical reaction to become ketene, and further hydrolyze to indenocarboxylic acid (Indene-Carboxylic-Acid, CA), and the carboxylic acid is in an alkaline solvent. The solubility of the phenolic resin is about 100 times higher than that of the photoresist in the non-photosensitive part, and the carboxylic acid produced also promotes the dissolution of the phenolic resin. The transfer of the mask pattern can be carried out by utilizing the different solubility of the photoresist and the non-photoresist to the alkaline solvent.

Exposure method:

a. The contact exposure (Contact Printing) mask is in direct contact with the photoresist layer.

b. A slight separation between the mask plate and the photoresist layer of proximity exposure (Proximity Printing) is about 10-50 μm.

c. Projection Printing. Exposure is achieved using a lens focused light between the mask and the photoresist.

d. Stepper exposure

Here is a special mention of the classification of projection exposure:

The two most important parameters in exposure are:

1. Exposure energy (Energy)

2.Focus

If the energy and focal length are not well adjusted, the graphics of the required resolution and size cannot be obtained. Appears as a graphic’s critical dimension is out of the required range.

6. Development

By adding the developer after the exposure process, the photosensitive area of the positive photoresist and the non-photosensitive area of the negative photoresist will be dissolved in the developer. After this step is completed, the pattern in the photoresist layer can be revealed. In order to improve the resolution, almost every type of photoresist has a special developer to ensure high-quality development.

The developing process makes the recessive pattern formed in the exposure process become the dominant pattern with and without the photoresist, which is used as the stencil for the next processing. The process of selective dissolution is carried out in the development, and the most important thing is the ratio of dissolution rate (DR) between the exposed area and the unexposed area. Commercial positive films have DR ratios greater than 1000, with a dissolution rate of 3000 nm/min in the exposed area and only a few nm/min in the unexposed area.

There are two development methods, one is wet development, which is widely used in IC and microfabrication, and the other is dry development.

a. The whole box of silicon wafer immersion development (Batch Development).

Disadvantages: The developer consumes a lot; the uniformity of development is poor;

b. Continuous Spray Development/Auto-rotation Development. One or more nozzles spray the developer on the surface of the silicon wafer, while the silicon wafer rotates at a low speed (100-500rpm). Nozzle spray pattern and wafer rotation speed are key tuning parameters to achieve reproducibility of wafer-to-wafer dissolution rate and uniformity.

c. Puddle Development (Puddle Development). Spray enough (not too much, to minimize backside humidity) of developer onto the wafer surface and form a puddle shape (developer flow is kept low to reduce edge development rate variation). The wafer is fixed or slowly rotated. Generally, multiple spin coating developers are used: the first coating, holding for 10 to 30 seconds, and removing; the second coating, holding, and removal. It was then rinsed with deionized water (to remove all chemicals from both sides of the wafer) and spun dry. Advantages: less developer dosage; uniform development of silicon wafers; minimized temperature gradients.

Developer:

a. The developer for positive photoresist. The developer level of the positive film is an alkaline aqueous solution. KOH and NaOH are generally not used in IC manufacturing because they will bring Movable Ion Contamination (MIC, Movable Ion Contamination). The most common positive gel developer is tetramethylammonium hydroxide (TMAH) (standard normality 0.26, temperature 15-250C). Carboxylic acid is generated during the exposure of I-line photoresist, and the neutralization of alkali and acid in TMAH developer solution dissolves the exposed photoresist in the developer solution, while the unexposed photoresist has no effect; in chemically amplified photoresist The phenolic resin contained in (CAR, Chemical Amplified Resist) exists in the form of PHS. The acid generated by the PAG in the CAR removes the protective group (t-BOC) in PHS, resulting in rapid dissolution of PHS in TMAH developer. During the whole developing process, TMAH did not react with PHS.

b, developer of negative photoresist. Xylene. The cleaning solution is butyl acetate or ethanol, trichloroethylene.

Common problems in development:

a. Incomplete Development. Photoresist remains on the surface. Caused by insufficient developer;

b, insufficient development (Under Development). The developed sidewall is not vertical, which is caused by insufficient development time;

c. Over Development. The photoresist near the surface is excessively dissolved by the developer, forming steps. Development time is too long.

6. Hard Bake

After the resist development is completed, the pattern is basically determined, but the properties of the photoresist need to be more stable. This is achieved by hard drying, a step also known as hardening. In this process, high temperature treatment can be used to remove the remaining solvent in the photoresist, enhance the adhesion of the photoresist to the surface of the silicon wafer, and improve the resistivity of the photoresist during subsequent etching and ion implantation. . In addition, the photoresist will soften at high temperature, forming a molten state similar to that of glass at high temperature. This rounds the photoresist surface under the action of surface tension and reduces defects (such as pinholes) in the photoresist layer, thus correcting the edge profile of the photoresist pattern.

The overall treatment of the sample with O2 plasma to remove possible undesired residues after development is called de-scumming. Especially for negative adhesives but also positive adhesives, a thin polymer layer will remain at the original adhesive-substrate interface after development. This problem is more serious in structures with structures less than 1um or large depth-to-width ratios. Of course, the thickness of the glue remaining will be reduced during the De-scumming process, but the effect will not be too great.

Finally, a hard bake is required to remove residual developer and water prior to etching or coating, and annealing is required to improve interfacial bonding due to penetration and swelling during development. At the same time, the hardness of the glue is improved and the etching resistance is improved. The hard baking temperature is generally as high as 120 degrees or more, and the time is also about 20 minutes. The main limitation is that the high temperature can make the edge of the pattern worse and difficult to remove after etching.

Method: Hot plate, 100~1300C (slightly higher than glass transition temperature Tg), 1~2 minutes.

Purpose:

a. Completely evaporate the solvent in the photoresist (so as not to contaminate the subsequent ion implantation environment, for example, nitrogen in the DNQ phenolic resin photoresist will cause the photoresist to partially burst);

b. Hard film to improve the ability of photoresist to protect the lower surface during ion implantation or etching;

c. Further enhance the adhesion between the photoresist and the surface of the silicon wafer;

d. Further reduce the standing wave effect (Standing Wave Effect).

common problem:

a. Underbake. Reduce the strength of the photoresist (etching resistance and blocking ability in ion implantation); reduce the pinhole filling ability (Gapfill Capability for the needle hole); reduce the adhesion to the substrate.

b. Overbake. The flow of photoresist is caused, the pattern precision is reduced, and the resolution is deteriorated. In addition, deep ultraviolet (DUV, Deep Ultra-Violet) can be used to harden the film. The positive photoresist resin is cross-linked to form a thin surface hard shell, which increases the thermal stability of the photoresist. In the subsequent plasma etching and ion implantation (125-2000C) processes, the resolution reduction caused by the high temperature flow of the photoresist is reduced.

7. Etching or ion implantation

Etching is a process in the manufacture of semiconductor devices that utilizes chemical means to selectively remove specific portions of a deposited layer. Etching is very important for the electrical properties of the device. If there is a mistake in the etching process, the silicon wafer that is difficult to recover will be scrapped, so strict process control must be carried out. Each layer of a semiconductor device undergoes multiple etching steps.

Etching is generally divided into electron beam etching and photolithography. Photolithography has high requirements on the flatness of the material, so high cleanliness is required. However, for electron beam lithography, the resolution is much better compared to lithography due to the extremely short wavelength of the electrons. Flatness requirements are not high because no mask is required, but e-beam etching is slow and expensive.

For most etch steps, portions of the upper layers of the wafer are protected by “masks” that cannot be etched, allowing selective removal of specific portions of the layers. In some cases, the material of the mask is photoresistive, similar to the principles used in photolithography. In other cases, the etch mask needs to be resistant to certain chemicals, and silicon nitride can be used to make such a “mask”.

Ion implantation is a technique in which specific ions are accelerated in an electric field and then embedded in another solid material. Using this technique can change the physicochemical properties of solid materials and is now widely used in semiconductor device fabrication and some materials science research. Ion implantation can cause nuclear transitions, or change the crystal structure of certain solid materials.

8. Removal of photoresist

The main function of the photoresist is to protect the portion of the substrate under the photoresist when chemical or mechanical processing processes are performed over the entire area. Therefore, after the above process is completed, the photoresist should be completely removed, and this step is referred to as stripping. Only those high temperature stable photoresists, such as photosensitive polyimide, can be left on the device as an intermediate or buffer coating.

To avoid any damage to the treated surface, mild chemical methods at low temperatures should be used. The application of ultrasound can also enhance the peeling performance. Because of corrosion problems, some known stripping solutions cannot work with metal surfaces such as aluminum; in this case, ozone or oxygen plasma (ashing) is used first. These plasmas are also successfully used as lithographic strippers for non-aluminum surfaces, however, damage to the device surface remains a problem to be solved.

After etching or ion implantation, the photoresist is no longer needed as a protective layer and can be removed. The methods of degumming are classified as follows:

Wet degumming

Organic solvent removal: remove photoresist with organic solvent

Inorganic solvent: By using some inorganic solvents, the carbon element in the photoresist is oxidized to carbon dioxide, and then it is removed

Dry stripping: stripping photoresist using plasma

In addition to these main processes, some auxiliary processes are often used, such as uniform etching of a large area to reduce the thickness of the substrate, or to remove uneven edges. Generally, in the production of semiconductor chips or other components, a substrate needs to be repeated many times for photolithography.

The above are the steps of photolithography, which are hereby collected for everyone, hoping to correct them.

The Links: LM64K102 LC171W03-B4K1