These days, motor control systems require higher performance, lower power consumption, and more functions including intelligent operation. In addition to precise motor control, a system needs to be able to perform simultaneous application execution, communicate with other devices, and detect operating anomalies. Furthermore, these systems require safety design along with security measures for network connectivity.

To help designers meet these requirements, Renesas developed the RA8T1 group of MCUs for motor control in the 32-bit RA microcontroller family. RA8T1 devices implement the latest high-end Cortex®-M class core which enables precise motor control and contributes to higher overall system power efficiency. In addition to the performance, RA8T1 also delivers abundant optimized features, enabling designers to adopt additional functions to their system. Expanding the optimized motor control product line to a lineup addressing low-end to high-end motor system demands allows design scalability as well as leverages common development tools and software.

At the high end of the portfolio, RA8T1 MCUs are built on the Arm® Cortex®-M85 core and operate up to 480MHz, offering large memory options of up to 2MB of Flash and 1MB of SRAM (incl. TCM), 16-bit/32-bit timers supporting complementary PWM output, 12-bit ADC including 3-ch sample and hold, and high-speed analog comparator for motor control. Connectivity features include Ethernet MAC, CAN FD, USB 2.0 Full-Speed module, SD/MMC host interface, and I3C. Moreover, the Armv8.1-M architecture supports Helium technology to significantly improve AI/ML calculation performance plus Pointer AuthentiCation and Branch Target Identification (PACBTI) and TrustZone® to enhance security.

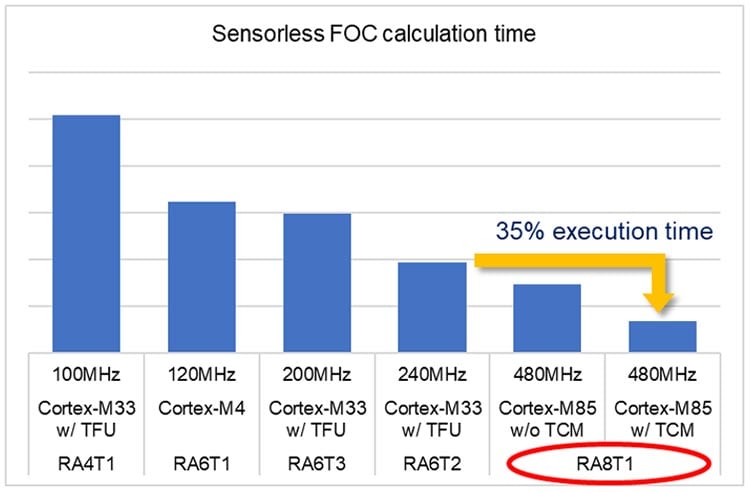

A key advantage of RA8T1 is its high performance. The motor control processing time of the RA8T1 is about a third of existing Cortex-M33 products when using sensorless field-oriented control (FOC) sample code. It clarifies that the excellent performance of the Cortex-M85 can be further maximized in RA8T1 by using TCM. See Figure 2.

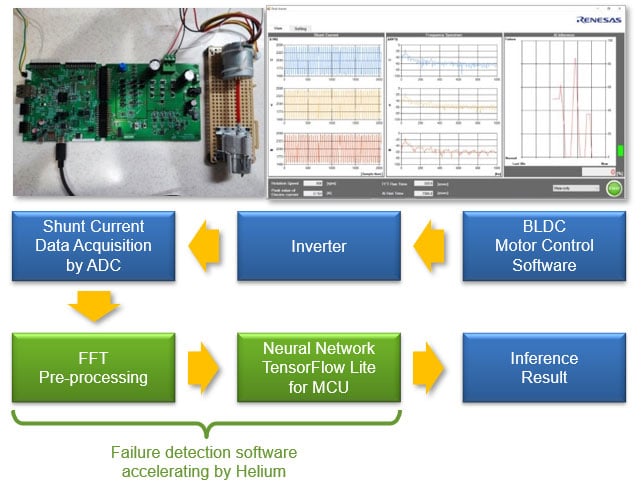

By compressing the processing time of the motor control in this way, it is possible to adopt additional features in the end system. For instance, let’s look at a predictive maintenance example. Using Renesas e-AI software, this demonstration analyzes the motor current captured by the A/D converter with 256 fast fourier transform (FFT) conversion and detects the anomaly in motor behavior using TensorFlow Lite as the inference engine. In this process, the inference time achieved is 5.3 times faster compared to the existing Cortex-M7 devices due to RA8T1’s support of Helium technology to perform more effectively.

In addition to predictive maintenance, RA8T1 enables the addition of more features to the system, such as network connection, safety function, security, and more.

Taking advantage of the above features, the RA8T1 targets motor/inverter control systems in a wide range of markets, such as industrial automation, building automation, smart homes, consumer products, and healthcare equipment.

Figure 5. RA8T1 Target Applications

Like all RA MCUs, the RA8T1 Group supports the Renesas Flexible Software Package (FSP), as well as extensive development environments including the MCK-RA8T1 motor control evaluation kit, sample code, QE for Motor, and Renesas Motor Workbench.

For more detailed information, including samples, evaluation kits, technical documents, sample code, and development support tools, visit the RA8T1 product page.

RA8T1 Motor Control Kit

Flexible Software Package (FSP)

QE for Motor: Development Assistance Tool for Motor Applications

Renesas Motor Workbench