“Indoor LED Display, the use of surface mount SMD display in the market has become a mainstream mature product, among which small spacing is widely used in conference rooms, courts, public security bureaus, procuratorates, command centers, TV stations, etc. At the same time, the channel sales method has been Widely distributed in shopping malls, restaurants, schools, public buildings and other places.

“

Indoor LED display, the use of surface mount SMD display in the market has become a mainstream mature product, among which small spacing is widely used in conference rooms, courts, public security bureaus, procuratorates, command centers, TV stations, etc. At the same time, the channel sales method has been Widely distributed in shopping malls, restaurants, schools, public buildings and other places.

For a general indoor LED display, the product is delivered in a state of zero faults, but after a period of use, there will be broken lights, column lights, and lights will fall out due to inadvertent collisions; during installation Unpredictable or unsatisfactory scenes sometimes appear in the scene environment, for example, the influence of the temperature difference between the air-conditioning tuyere and direct blowing at close range causes large-scale dead spots, or the scene environment is too humid, resulting in damage to the screen. The point rate is increasing day by day.

For the indoor small-pitch industry that has passed the half-year inspection, how to solve the display screen problems caused by factors such as water vapor, dust, bumps, and bad lamp rates, as well as improve product quality and reduce the burden and cost of after-sales service, are the current LED manufacturers want to problem to be solved.

Figure 1. Short circuit and column bright phenomenon of bad LED display

Therefore, in order to effectively solve the mentioned problems, so-called surface coating solutions have been created.

Such a solution is based on the current indoor surface mount LED display, and the equipment can be directly combined with the current existing SMT surface mount production line, as shown in Figure 2.

Figure 2. Schematic diagram of surface coating equipment (lamp surface)

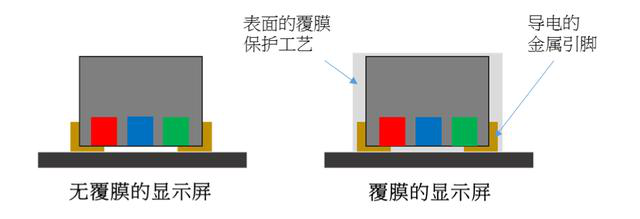

The process is to make the light board produced by the (SMT) surface mount process, and after 72 hours of aging process, the surface of the light board is covered with a surface film to form a so-called protective layer, which can wrap the conductive pins and isolate them. Moisture and moisture effects, as shown in Figure 3.

For LED display products with a general protection level of IP40 (IPXX, front X dustproof, rear X waterproof), it has the technology to effectively improve the protection level of the LED lamp surface, provide anti-collision effect, avoid the occurrence of light failure and reduce the dead point of the whole screen At present, this type of solution has already met the market demand and is mature in production, and will not excessively increase the overall cost burden.

Figure 3. Schematic diagram of the surface coating process

Not only that, the protection process on the back of the printed circuit board (PCB) maintains the three-proof paint protection process used in the past (as shown in Figure 4). Generally, the protection level of the back of the circuit board can be improved by spraying. The surface (IC) is coated with a film to form a protective layer to avoid failure of the integrated circuit components of the drive circuit.

Figure 4. Schematic diagram of surface coating equipment (IC surface)

For LED display modules used indoors, such a solution can effectively prevent the occurrence of problems such as failure points caused by moisture and dust by covering the exposed electrical conductive pins, and at the same time can provide protection The effect of bumping, the current surface coating solutions on the market include GOB display, AOB display, etc. Table 1 is a comparison with the general SMD display.

Table 1 Comparison with general SMD display