integrated circuit

Integrated circuit (Integrated circuit) is a kind of miniature

electronic device. It uses a certain process to interconnect the transistors, resistors, capacitors, inductors and other components and wiring required in a circuit on a semiconductor substrate, and then encapsulate them in a tube. Inside the shell, a miniature structure with the required circuit functions is formed.

The first integrated circuit was invented by Jack Kilby of Texas Instruments, but it was not in the form of integrated circuits today.

Popular Science: The Origin of Semiconductors

It was originally connected by separate wires. Earlier, Jean Horni (Jean Horni) of Fairchild Camera has developed a planar manufacturing process that forms electronic junctions on the chip surface to make transistors. That is, the advantage that silicon is easy to form insulator silicon oxide. Then Robert Noyce (Robert Noyce) applied this technology to connect discrete devices previously formed on the silicon surface, and finally formed the pattern used by all integrated circuits.

Crafts and trends

Since 1947, the semiconductor industry has begun to improve and develop in technology, and it is still developing today. Process improvements can be attributed to two categories: process and structure.

Process improvement: to manufacture devices and circuits in smaller sizes, so that they have higher density, more quantity and higher reliability.

Structural improvements: inventions in the design of new devices make their performance better, achieve better energy consumption control and higher reliability.

The effects of these two improvements can be well understood from the development history of the

IGBT generations. Of course, many of the factors we mentioned before, such as some defects in the equipment process, can be attributed to the improvement of the process.

The size and quantity of devices in integrated circuits are two common signs of IC development. The size of the device is represented by the smallest size in the design, which we call the feature pattern size. The development from small-scale integrated circuits to today's millions of chips has benefited from the reduction in the feature pattern size of a single element, which has benefited from the tremendous improvement in the patterning process of the lithography machine and the multilayer wiring technology. This point is also discussed more today, such as 22nm chips, 10nm or even 7nm and so on. A more professional expression is the gate width, that is, we control the width of part of the gate. Smaller and faster transistors and higher-density circuits benefit from smaller gate width.

Moore’s Law does not develop unlimitedly over time. It is mainly limited by the limitations of semiconductor materials and preparation. Therefore, you will hear the news that the semiconductor material silicon is reaching its limit. Therefore, it is necessary to develop new materials and constantly upgrade equipment and design.

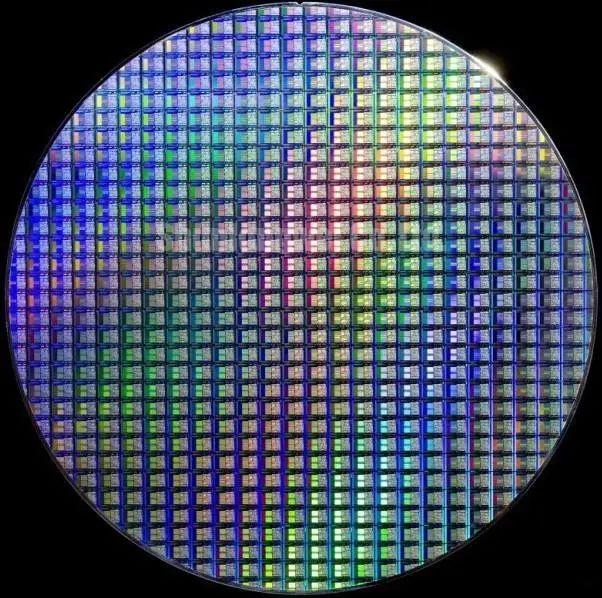

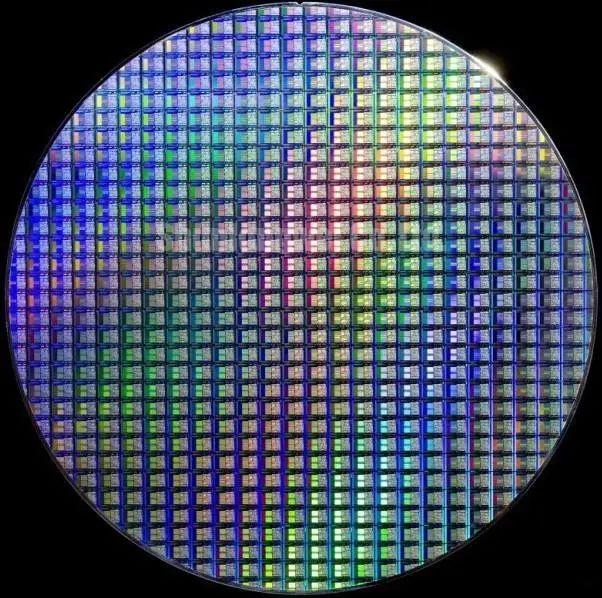

Chip and wafer size

We all know that chips are made on thin wafers of silicon or other semiconductor materials called wafers.

Popular Science: The Origin of Semiconductors

Making rectangular chips on a round wafer resulted in some unusable areas remaining at the edge of the wafer. When the chip size is larger, these unusable areas will also be larger, so larger wafers are gradually adopted, which also "reduces" the size of the chip in disguise, and also enables a certain degree of production efficiency and yield. Upgrade, this is one of the reasons why wafers from 6 inches to 8 inches to 12 inches are now.

Now the chip size is getting smaller and smaller, the cost is getting lower and lower, and the performance is getting higher and higher. Thanks to the process improvement and equipment development we mentioned above, this has also led to more and more fierce competition in the semiconductor industry. .

For now, there are roughly three types of manufacturers: Integrated Device Manufacturers (IDM): integrate design, manufacturing, packaging and sales; Foundry: other chip suppliers make chips; no processing plants (Fabless ): Only responsible for chip design and sales, and most other links are outsourced. Of course, there are other staggered models. At the same time, the localization of semiconductors has led to more and more domestic semiconductor manufacturers and more and more business models.