“Flexible screens will subvert the presentation of traditional screens, and enable society to enter an era where even a bottle of Coke can be displayed. Before this huge change, we need to make a summary of the current screens in the past.

“

Flexible screens will subvert the presentation of traditional screens, and enable society to enter an era where even a bottle of Coke can be displayed. Before this huge change, we need to make a summary of the current screens in the past.

1. Types and basic principles of touch screens

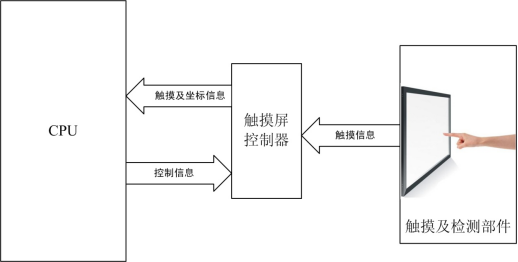

In order to facilitate the operation, people use a touch screen instead of a mouse or keyboard. As shown in Figure 1, the touch screen consists of a touch detection component and a touch screen controller; the touch detection component is installed on the front of the Display screen to detect the user’s touch position and send it to the touch screen controller after receiving it; while the main function of the touch screen controller is from the touch The point detection device receives the touch information, converts it into contact coordinates, and sends it to the CPU. It can also receive the commands sent by the CPU and execute them.

Figure 1 Block diagram of touch screen system

According to the working principle of the touch screen and the difference of the transmission information medium, we divide the touch screen into four types, namely resistive type, capacitive sensing type, infrared type and surface acoustic wave type. Each type of touch screen has its own advantages, disadvantages and applicable occasions. Here is a brief introduction to the various types of touch screens mentioned above:

1. Resistive touch screen

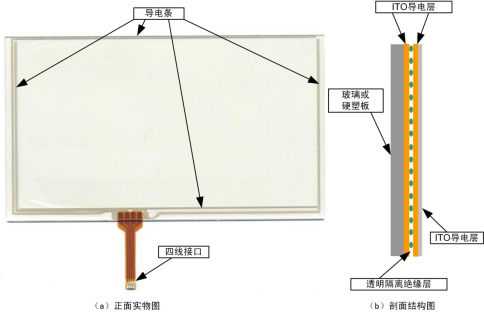

This touch screen uses pressure sensing for control. As shown in Figure 2, the main part of the resistive touch screen is a resistive film screen that fits well with the surface of the display. This is a multi-layer composite film. It uses a glass or hard plastic plate as the base layer, and the surface is coated with a transparent layer. The conductive layer of oxidized metal (transparent conductive resistance) is covered with a layer of hardened outer surface, smooth and scratch-resistant plastic layer, and its inner surface is also coated with a layer of coating, and there are many small (less than 1 /1000 inch) transparent isolation point separates the two conductive layers and insulates. When a finger touches the screen, the two conductive layers are in contact at the touch point, the resistance changes, and signals are generated in both the X and Y coordinates, and then sent to the touch screen controller. The controller detects this contact and calculates the position of (X, Y). This is the most basic principle of resistive technology touch screens.

The key to resistive touch screens lies in material technology. Commonly used transparent conductive coating materials include indium oxide (ITO) and nickel-gold coatings.

Figure 2 Structure diagram of four-wire resistive touch screen

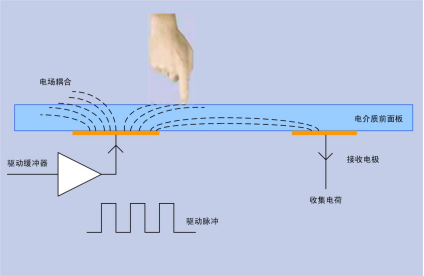

2. Capacitive touch screen

The capacitive touch screen works by using the current induction of the human body. When a finger touches the metal layer, due to the electric field of the human body, the user and the surface of the touch screen form a coupling capacitor. For high-frequency current, the capacitor is a direct conductor, so the finger draws a small current from the contact point. This current flows from the electrodes on the four corners of the touch screen, and the current flowing through these four electrodes is proportional to the distance from the finger to the four corners. The controller calculates the position of the touch point by accurately calculating the ratio of these four currents. .

Figure 3 Working principle of capacitive touch screen

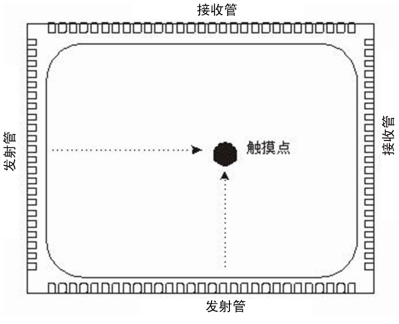

3. Infrared touch screen

The infrared touch screen uses the infrared matrix densely distributed in the X and Y directions to detect and locate the user’s touch. As shown in Figure 4, the infrared touch screen is equipped with a Circuit board outer frame in front of the display. The circuit board arranges infrared emitting tubes and infrared receiving tubes on the four sides of the screen to form a horizontal and vertical cross infrared matrix in a one-to-one correspondence. When the user touches the screen, the finger will block the horizontal and vertical two infrared rays passing through the position, so the position of the touch point on the screen can be judged. Any touch object can change the infrared ray on the contact to realize touch screen operation.

Figure 4 Principle of infrared touch screen

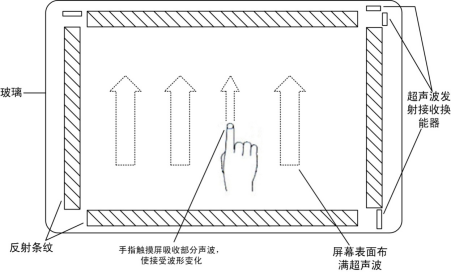

4. Surface acoustic wave touch screen

Surface acoustic waves are a kind of ultrasonic waves, which are mechanical energy waves that propagate shallowly on the surface of a medium (such as rigid materials such as glass or metal). As shown in Figure 5, the upper left corner and the lower right corner of the touch screen are respectively fixed with vertical and horizontal ultrasonic transmitting transducers, and the upper right corner is fixed with two corresponding ultrasonic receiving transducers. The four peripheries of the glass screen are engraved with very precise reflection stripes with a 45° angle ranging from sparse to dense. Take the X-axis transmitting transducer in the lower right corner as an example: the controller controls the transmitting transducer to emit sound wave energy and transfer it to the left surface, and then the reflection fringe at the bottom of the screen reflects the sound wave energy into an upward uniform surface for transmission; the sound wave energy passes through On the surface of the screen, the reflection fringes on the top of the screen are gathered into a rightward line and propagate to the X-axis receiving transducer. The receiving transducer converts the returned surface acoustic wave energy into an electrical signal. When there is no touch, the waveform of the signal received by the receiving transducer is exactly the same as the reference waveform. When a finger or other object capable of absorbing or blocking sound wave energy touches the screen, the sound wave energy going up on the X axis through the finger part is partially absorbed, reflecting that there is an attenuation gap in the waveform on the received waveform, that is, at a certain moment. According to the position of the attenuation notch in the waveform, the X-axis coordinate of the touch can be calculated, and the Y-axis coordinate can be obtained in the same way.

Figure 5 Surface acoustic wave touch screen

What are the specific applications of touch screens? How to calculate the XY coordinates during design? What are the commonly used resistive screen driver chips? There will be an analysis later.

This article only briefly introduces the current mainstream display types in embedded hardware design. With the development of Industry 4.0, embedded devices have spread across various industries. ZLG Zhiyuan Electronics embedded products have accumulated nearly 20 years of design experience, and fully guarantee the stability of the product from the aspects of the product’s RTC clock, power management, ESD protection circuit, and various communication interfaces. ZHIYUAN Electronics started from the 8-bit microcontroller program design in 2001, and gradually mastered the ARM7, ARM9, Cortex-A7, A8, A9, M7 and the most cutting-edge A53 processor application technology of the ARM system. It has a full range of industrial-grade ARM cores. Board and industrial computer. At the same time, based on the understanding and accumulation of embedded technology, we independently research and develop the next-generation software development platform-Aworks real-time operating system to help users quickly realize product development based on a stable software and hardware platform, based on ZLG industrial-grade core board/industrial control board development Products have been widely used in power, rail transit, industrial sites, medical and other occasions where product reliability is more demanding, and continue to provide a complete set of industry application solutions for various industries.

The Links: RM10TA-24 NL6448BC20-18