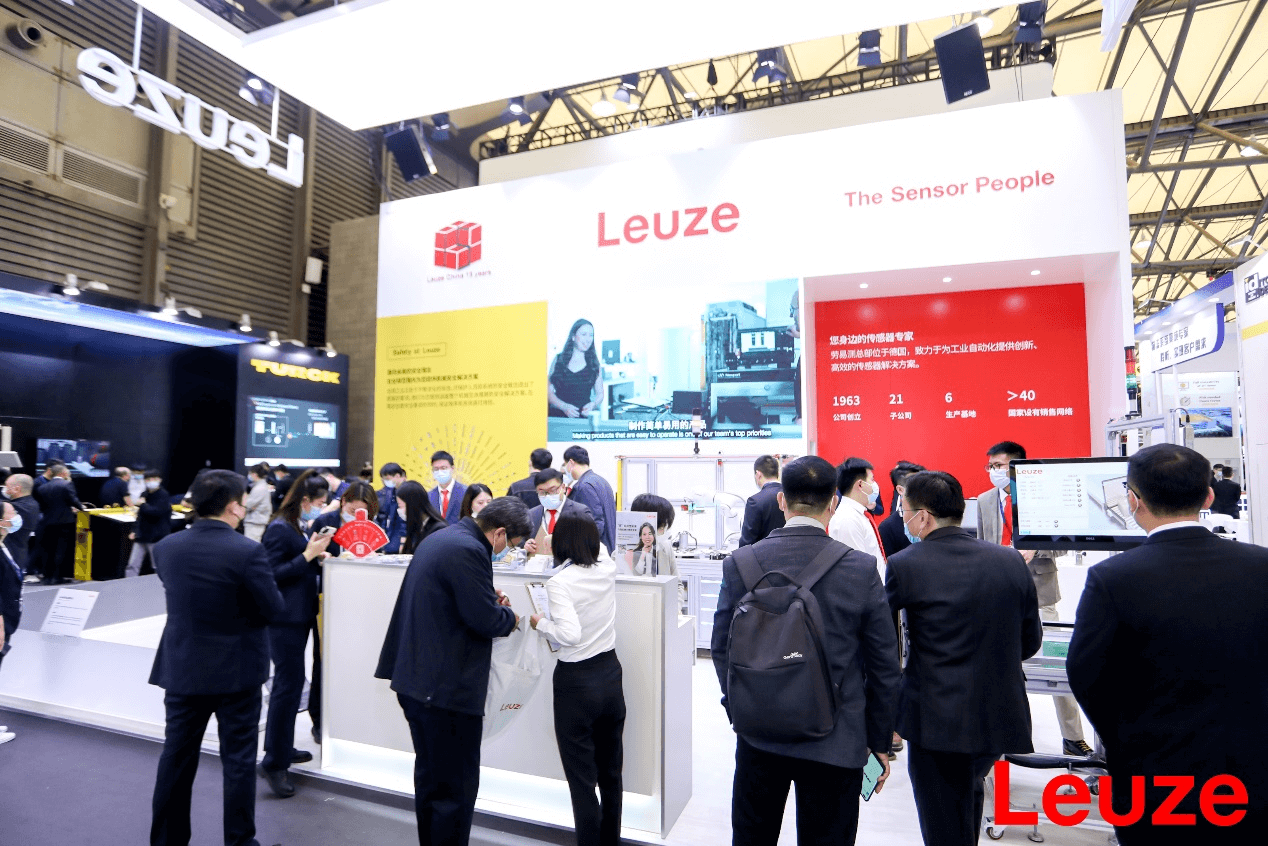

On October 26, the 2021 CeMAT ASIA exhibition was grandly opened at the Shanghai New International Expo Center. As an industry indicator, CeMAT ASIA gathers many innovative products and solutions in various fields of logistics equipment, demonstrating the rapid development of logistics technology.

(Photo courtesy of the enterprise, below)

Logistics technology is developing in the direction of intelligence and flexibility

Since the mid-1970s, China began to build the first automated three-dimensional warehouse, and half a century since the development of the first automatic sorter, China’s logistics technology has undergone tremendous changes. Although it started late and the process was rugged, it eventually came from behind.

On the one hand, with China’s reform and opening up, a large number of multinational companies such as Wal-Mart began to establish global sourcing centers in China to provide a foundation for the development of logistics technology; subsequently, leading companies in representative industries such as electronics, home appliances, and tobacco The start of self-built automated logistics system has significantly accelerated the development of logistics technology; the rise and rapid development of e-commerce has greatly stimulated the development of logistics technology; in addition, as the global manufacturing industry begins to gradually transfer to China, the world’s advanced Logistics technology and solutions have also been transferred to China to provide assistance for the development of logistics technology…

Driven by the combined forces of many factors, China’s logistics technology has completed the transformation from manual operations to semi-automation to automation. Significant progress has been made in technology types, quality, and product development and innovation, and logistics equipment has become more abundant. The functions are constantly being improved, and are being upgraded and developed in the direction of intelligence and flexibility.

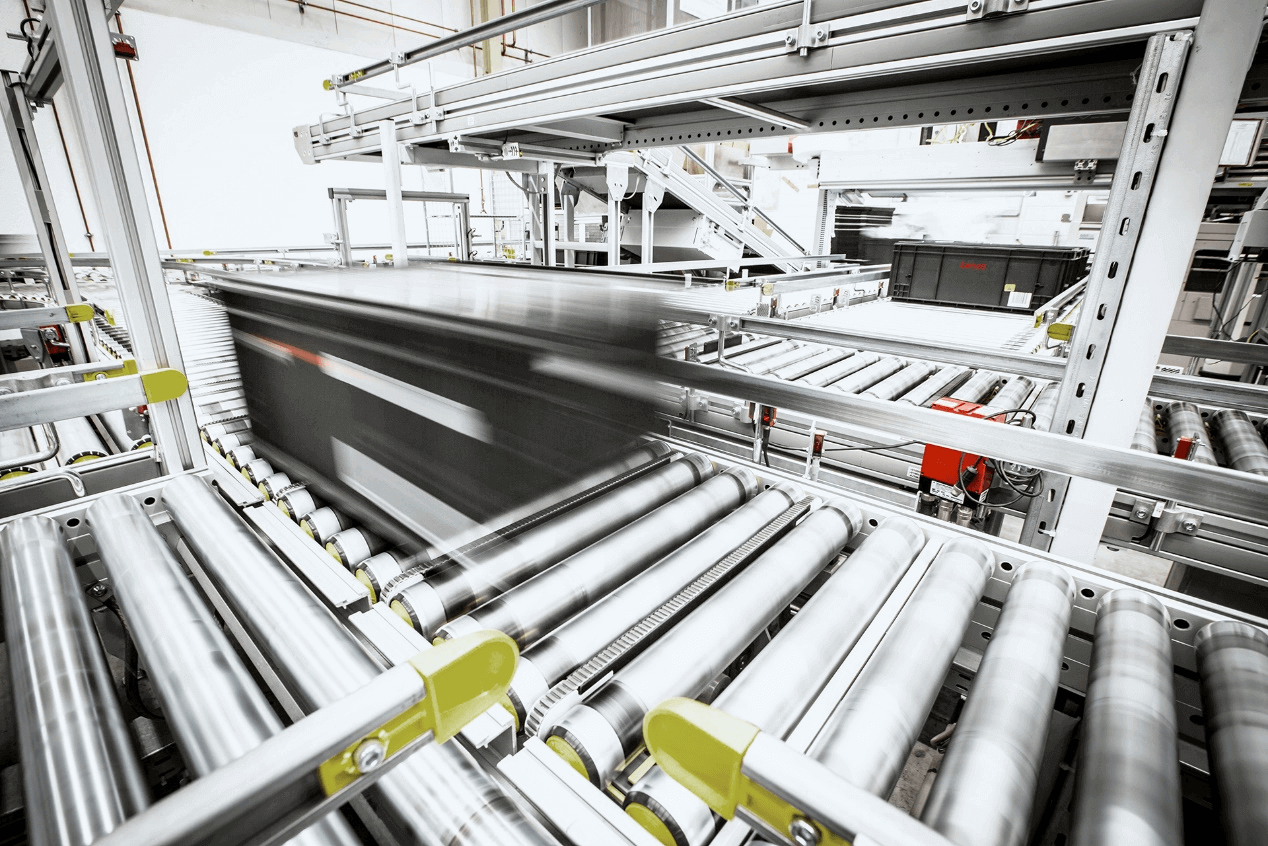

This trend has been fully reflected in the CeMAT ASIA exhibition in recent years. From the perspective of the types of intelligent equipment, the types of logistics technologies and solutions used in storage, picking, sorting, transportation and handling scenarios have been continuously enriched. Products such as high-efficiency multi-passing systems and “goods-to-person” picking technologies such as Kiva robots and four-way shuttles that have attracted market attention in recent years, robotic picking technologies, high-speed sorting systems, and so on. From the perspective of product performance and intelligence, it is also constantly upgraded. For example, the walking speed of the stacker crane has gradually developed from the initial average of 20m/min to the current 200m/min, 240m/min, etc., with positioning accuracy and accurate operation. Degrees and so on are all increasing simultaneously. In addition, with the shortage of land resources and the increase in land use costs, intensification has also become one of the trends. Under the rapidly changing market demand, more flexibility and flexibility are also important development directions for logistics equipment.

Behind the continuous intelligent upgrade of logistics equipment, it is inseparable from the upgrade and iteration of sensor technology.

Sensors are the basis for the realization of intelligent manufacturing and intelligent logistics. It is precisely because of the existence of sensors that logistics equipment have “eyes”, with “sensing” and “interaction”, which can support logistics equipment to be more efficient, accurate and safe. , Stable and flexible operation and operation. At the same time, as the sensing device of logistics equipment, sensors are constantly upgrading along with the development of logistics technology.

For example, the reason why the stacker mentioned above can achieve a leap-forward increase in walking speed is the emergence and development of sensor products such as long-distance laser ranging, which can make the high-speed stacker become what it is today. Normal product.

Sensor technology development and technological innovation

The upgrading and development of sensor technology, and even the changes in the demand of the entire logistics equipment industry, can be “a glimpse of the whole world” through the key display products of the industry’s representative company Leuze at CeMAT ASIA this year.

Zhu Fengjing, Director of Key Accounts, Leuze Logistic Industry

1.Security is getting more and more important

After considerable development, China’s logistics equipment industry has gradually narrowed the gap with foreign advanced levels in terms of operating efficiency indicators and fault-tolerant intelligence, and even achieved leadership in some areas. However, according to Zhu Fengjing, director of major customers in the logistics industry of Leuze, there is still a big gap in the safety concept of China’s logistics equipment.

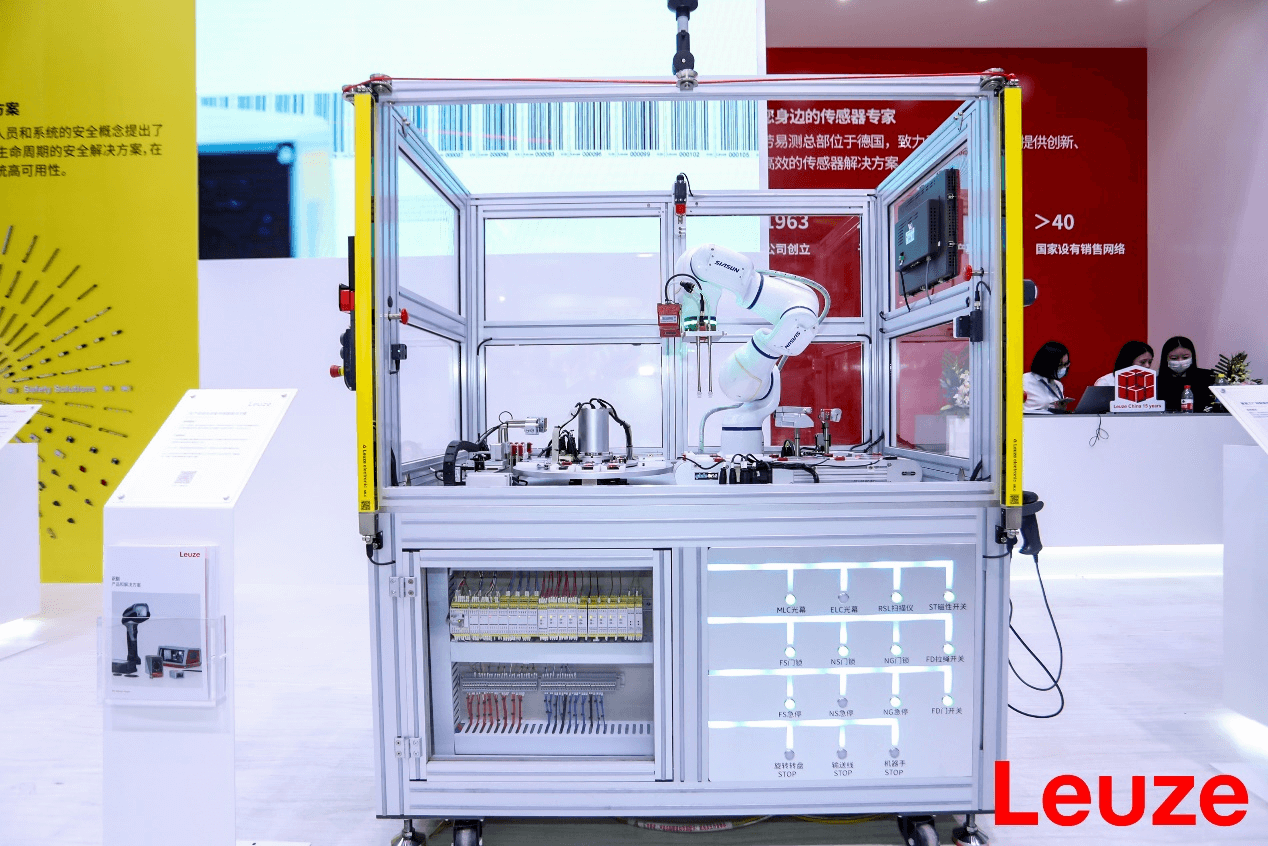

With the increasing application of automation equipment, the safe and stable operation of equipment is the basis for ensuring its efficient functioning; at the same time, with the increase of human-computer interaction and human-computer collaborative operation scenarios, how to ensure the safety of automation equipment and personnel is increasing Valued. “Safety at Leuze” is one of the themes of Leuze’s presentation.

The logistics industry security solutions highlighted by Leuze in this exhibition mainly include:

Safety light curtain MLC 500 series: used for safety protection at the entrance and exit of the operating area, with the following certifications: T?V Süd, cCSA US, cT?V NRTL US, S Mark. The light curtain is easy to install and does not require additional software for setting functions.

Safety door lock NG series: Integrate multiple buttons for control and signal indication functions. The buttons in the switch can be connected through the press-fit spring-connected terminal. The locking force is F1max=9750N, which saves space and is easy to clean.

Safety 3D radar system LBK: It is capable of safety protection in harsh environments. It is specially developed for monitoring hazardous areas in harsh industrial environments. The system can detect human bodies and monitor the entry and stay of people in the protected area.

There is also a blockbuster new product coming on the market: the secure barcode positioning system FBPS 600i: only one sensor is needed for secure location detection. It is suitable for high-performance application level PLe security level. The safety function can be realized very easily, and can save the time and energy required for installation and maintenance cost. The fault response time of 10ms is especially suitable for high-speed stacker equipment, and the high depth of field range of 50~170mm can have good compatibility with mechanical installation accuracy.

“Decades of safety technology accumulation and practice, and in-depth understanding of various standards are the basis of Leuze safety solutions. We provide customers with safety products and services covering the entire machinery life cycle to meet safety requirements. At the same time, the efficiency and high availability of the system are guaranteed.” Zhu Fengjing emphasized.

2.New sensors meet diverse needs

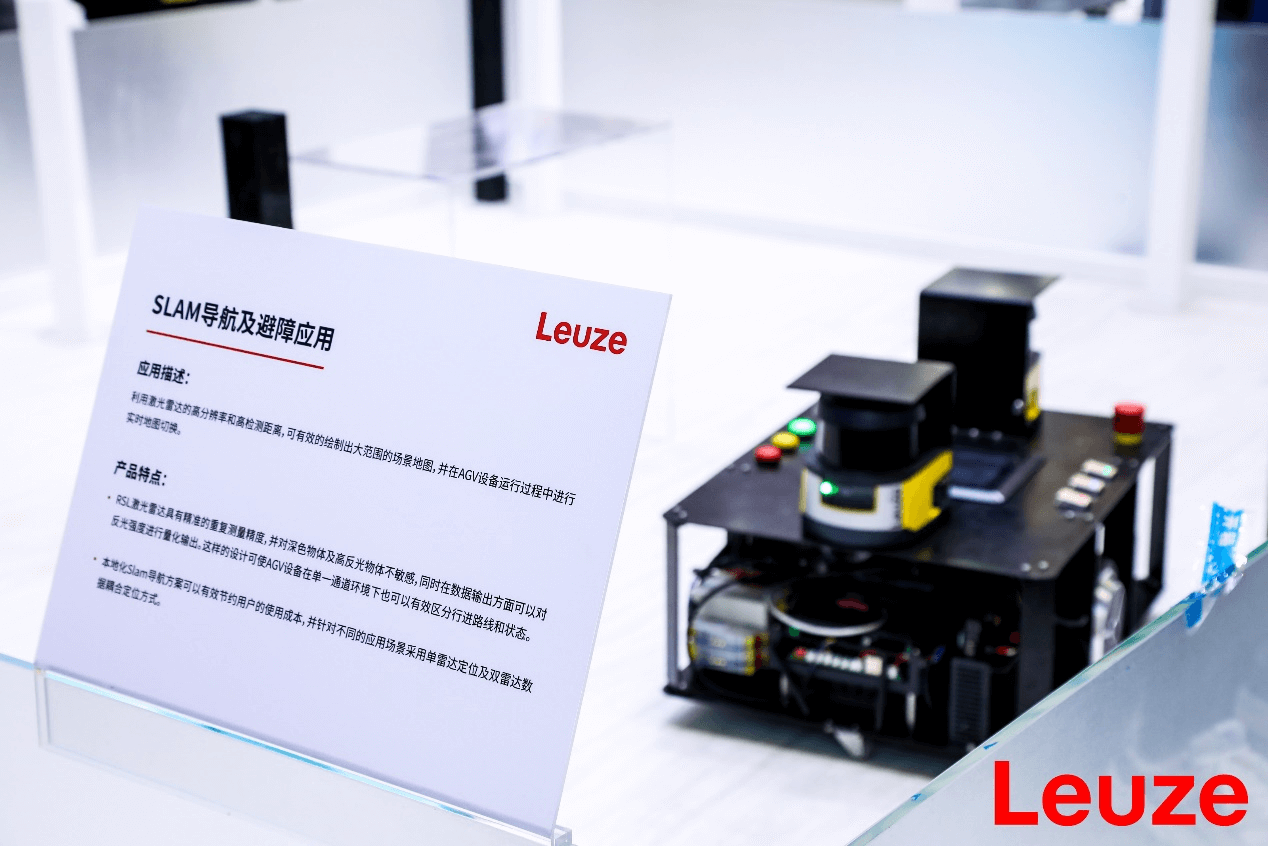

As mentioned earlier, with the continuous enrichment of types of logistics equipment, technological development and performance upgrades, and the increasing complexity of engineering projects, the demand and requirements for sensors are gradually increasing. For example, based on the development of navigation methods, AGV products have become a category that has developed rapidly in recent years and has attracted much attention. Its navigation methods have evolved from early magnetic strip navigation to two-dimensional code navigation and SLAM navigation.

l For SLAM navigation and obstacle avoidance applications, the RSL laser scanner displayed by Leuze has accurate repeat measurement accuracy and is insensitive to dark objects and highly reflective objects. At the same time, it can quantify the intensity of reflections in terms of data output. . Such a design allows the AGV equipment to effectively distinguish the travel route and status in a single channel environment.

l In response to the rapid development of e-commerce, express delivery and other industries and the resulting huge demand, Leuze highlighted the plug-and-play volume measurement system CMS 700i, through the quick-connect measurement light curtain product portfolio, and integration Algorithms can efficiently lay out the entire warehouse. The plug-and-play volume measurement system allows customers to easily operate.

In addition to empowering smart logistics, sensor technology is also an important support for smart manufacturing. Zhu Fengjing said that industry 4.0 has been proposed in China for many years. Although countries have different understandings and different power points, as the basic sensor equipment, the perception mission of realizing interconnection is always the same. Therefore, at this year’s exhibition, Leuze also focused on showing sensor solutions for production automation equipment and new bus technology as standard in smart factories. in:

l The 3C series sensor in the sensor solution of production automation equipment can ensure that materials can be reliably detected under tight arrangement, and can effectively avoid possible light interference caused by the lighting source of the production line; the DCR 200i QR code reader is compact Type design, can easily cope with various complex decoding environments.

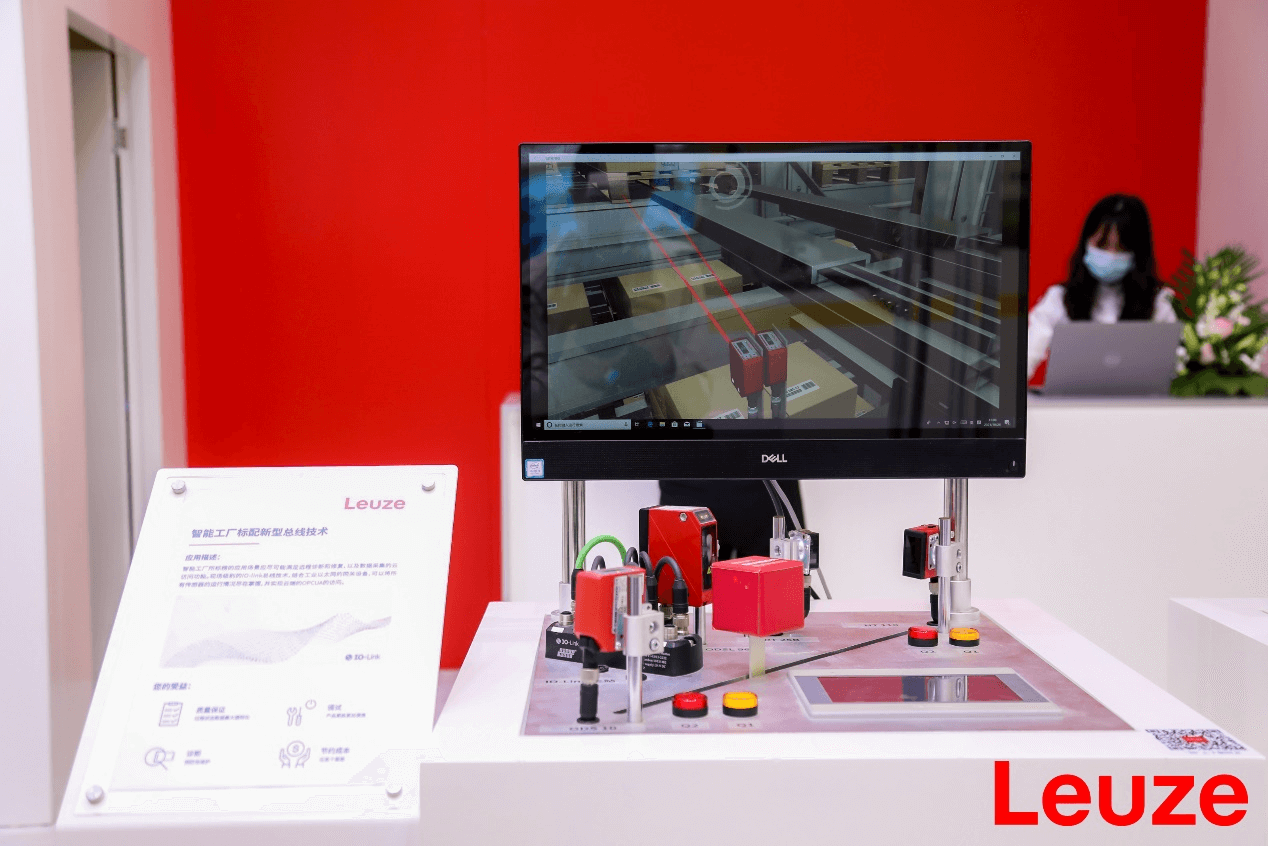

l Field-level IO-link bus technology, combined with industrial Ethernet gateway equipment, can fully grasp the operating conditions of all sensors, and achieve cloud-based OPCUA access to meet the remote diagnosis and repair and data required by smart factories Collected cloud access function.

3.Sensor technology innovation goes beyond

In addition, the upgrade iteration of sensor products is also reflected in the continuous improvement of response frequency, gradual reduction in volume, gradual integration of sensor applications and mechanical design of logistics equipment, etc., and the types of devices with bus functions are also increasing. The bus based on RS485 underlying technology is gradually converted into high-speed network equipment based on Ethernet and so on.

“As an important basic component in logistics equipment, sensors are highly efficient, stable, low-cost and flexible development are the focus of our future attention.” Zhu Fengjing added, “New technologies are never lacking, and cool technologies will always exist. As a sensor expert rooted in the logistics industry for more than decades, Leuze first thinks of the convenience of the customer’s use and operation and the suitability of the working conditions in the product development, and actively invests in the iterative development of products and the application of new technologies. It is the direction of Leuze’s continuous efforts to develop sensor products that better meet the needs of China’s smart equipment.”

Sensor technology empowers the development of smart logistics

Leuze, the German company founded in 1963, is one of the world’s leading optical sensor technology experts and industrial 4.0 IIOT (Industrial Internet of Things) solution innovators. It began to pay attention to sensors in the stack as early as around 1980. The application of palletizers and other logistics equipment has entered the Chinese market for 15 years. Adhering to the company development philosophy of “In China, For China”, we continue to expand the localization investment in R&D, production, logistics centers and sales services, quickly respond to the needs of the Chinese market, and serve customers with high quality . For the further development of the Chinese market in the future, Zhu Fengjing also expressed sufficient confidence.

In fact, after years of rapid growth, the potential of China’s logistics equipment industry is still optimistic about the world.

First of all, the economy is the foundation of all development. From the perspective of the overall macroeconomic development, my country is currently undergoing “a major change unseen in a century.” Since the reform and opening up, the economy has developed rapidly and has become the world’s second largest economy. According to a recent public speech by economist Lin Yifu, Honorary Dean of the National Development Research Institute of Peking University, China has the advantages of traditional industries and the advantages of overtaking in corners. For example, the fourth industrial revolution has brought new opportunities;artificial intelligenceNew technologies such as (AI), big data, and the Internet of Things make product development cycles particularly short; China has abundant human resources and the most complete real economy in the world’s supply chain. Therefore, there will be an average of 8% per year before 2035. Growth potential (actually can reach a growth of about 6%). At this rate, by 2030, China will become the world’s largest economy. As a pillar industry of our country, logistics is bound to usher in greater development and provide huge opportunities for logistics equipment.

From the perspective of the development of the industry itself, intelligence is undoubtedly the general trend. Unmanned warehouses, unmanned vehicles, drones and other unmanned systems have also begun to be gradually realized. With the development of smart logistics and smart manufacturing, the demand for sensors is bound to be Expand further. Correspondingly, with the continuous innovation and upgrading of sensor technology, the intelligent development momentum of China’s logistics equipment will be further highlighted!

Leuze

Sensor experts by your side

With a thirst for knowledge and determination, Leuze’s sensor experts have devoted themselves to innovation and a milestone in industrial automation technology for more than 50 years. The success of our customers is our motivation. Yesterday, today, tomorrow, always the same.

Leuze has a rich product line, including switch sensors, measuring sensors, identification systems, data transmission and image processing solutions. As a safety expert, Leuze also focuses on mechanical safety products, services and solutions, focusing on applications in core fields such as logistics, packaging, machine tools, automobiles, laboratory automation, electronics, lithium batteries, photovoltaics, and rail transit, and accumulates in these fields He has gained a lot of professional application technology and rich experience.

Leuze was founded in 1963 and is headquartered in Owen/Teck, southern Germany. Today, more than 1,200 sensor experts from Leuze’s global technical competence center and 21 sales subsidiaries, with their rich experience and firm commitment, with the full support of more than 40 international distributors, ensure that they help customers in the ever-changing Long-term success in the market.