[Introduction]Traction drives are the source of almost all energy consumption in electric vehicles (EVs). The drive system must therefore be as efficient as possible while occupying the least amount of space with the lowest possible weight – all with the aim of maximizing the range of electric vehicles. As the industry utilizes dual drives to increase traction while reducing losses with an 800 V architecture, the industry also needs inverters that shrink in size but increase output power to achieve power well beyond the capabilities of silicon (Si)-based technologies such as IGBTs density.

Wolfspeed’s latest generation of silicon carbide (SiC) power modules is designed to meet these demands with lower losses, higher power density and smaller size.

This article presents the reference design of the CRD600DA12E-XM3 three-phase dual inverter and shows how the corresponding components, including the CAB450M12XM3 power module and CGD12HBXMP gate driver, and other key technologies can be combined in a next-generation electric vehicle traction solution.

System Overview

The CRD600DA12E-XM3 contains two sets of CAB450M12XM3 power modules, each with CGD12HBXMP gate drivers (Figure 1). The overall design goal is to maximize performance with a low cost, low complexity, high ampacity, low inductance design.

Figure 1. System block diagram (left) showing three main components: two converter modules, each with a gate driver, and the controller. The exterior of the dual inverter enclosure (C) also shows the power module (A) mounted on the cold plate and the power core (B) with the gate driver. A handle and base are provided for easy portability. D shows a cross section of 204 mm x 267.5 mm.

When designing a system, there are five key points to consider:

● High power density achievable using Silicon Carbide (SiC) technology. While Silicon Carbide (SiC) supports operation at higher temperatures, high power densities require advanced heat dissipation techniques.

● Fast switching speed makes the system more prone to overshoot and ringing caused by stray inductance; therefore, the stray inductance of the busbar structure needs to be reduced.

● In response to this problem, it is also necessary to use low-inductance, high-ripple rated capacitors, and pay attention to reducing the size.

● The gate driver circuit must have sufficient drive strength to maintain the switching speeds required and supported by the silicon carbide (SiC) technology.

● The overall power density should be significantly higher to meet the requirements of the end application.

Preferred Power Module Platform: XM3

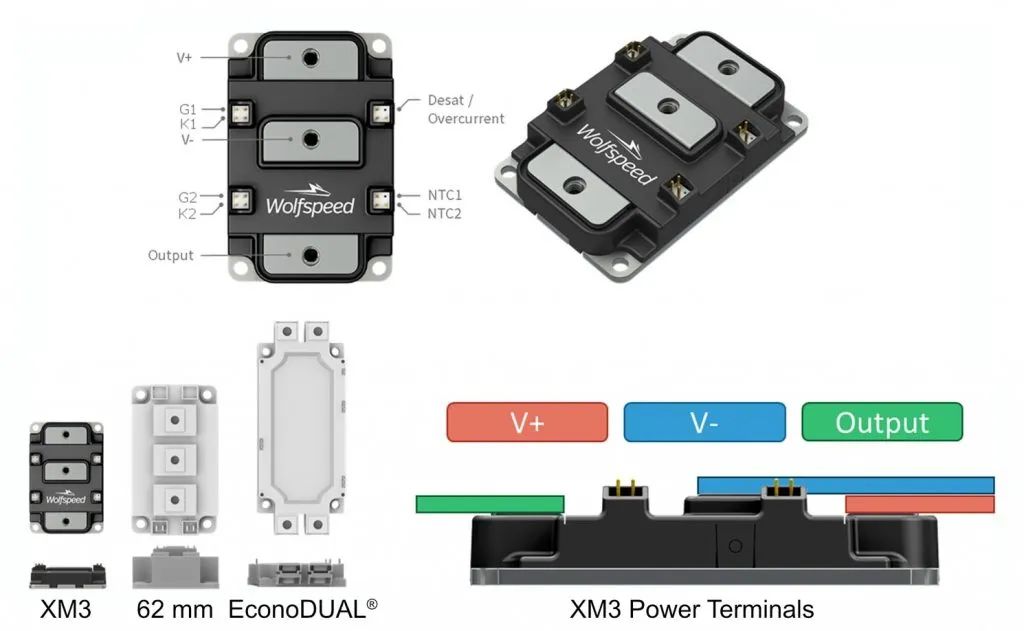

Power modules based on the Wolfspeed XM3 full silicon carbide (SiC) platform with excellent power density are the obvious choice. It is about half the weight and volume of a standard 62 mm module, and the difference is even more pronounced when compared to the EconoDUAL (Figure 2).

Figure 2. XM3 module (top), size comparison (bottom left), and side view showing XM3 non-planar power cables (bottom right)

The XM3 platform is designed with an overlapping planar structure for low stray inductance. The current loops within the module are both wide and thin, and are evenly distributed among the devices, creating an equivalent impedance at the switch location. The module’s power terminals can also be vertically offset, allowing a simple busbar design between the DC link capacitors and the module to be laminated all the way to the module. The net result is that the stray inductance of the power loop is only 6.7 nH at 10 MHz.

The module has half the stray inductance of industry standard modules and is less than half the size, with a 53 × 80 mm form factor. The XM3 platform offers switch-optimized and conduction-optimized products for different target applications, such as the CAB450M12XM3 1200 V, 450 A half-bridge module used in this system.

XM3 features include: an integrated temperature sensor for low-side switch positions; built-in voltage sensing (de-sat) connections for easy driver integration; and a high-reliability silicon nitride (Si3N4) power substrate for enhanced power cycling capabilities.

The performance of an inverter system can be further enhanced by several techniques, which can improve heat dissipation efficiency, reduce parasitic inductance, and reduce component count and size.

cold plate

The high current densities supported by silicon carbide (SiC) devices require high performance thermal stacks to maximize thermal conduction. Among the many options for heat sinks, extruded copper tubing is a common economical option for liquid cooling plates. Although it is possible to use a thin copper tube cold plate (about 12.7 mm) that supports the installation of modules on both sides, the disadvantages of different high thermal resistance on both sides and high pressure difference do exist, which can lead to inconsistencies in cooling between the surface and both sides.

The CRD600DA12E-XM3 uses Wieland Microcool’s Micro Deformation Technology (MDT) in the cold plate (Figure 3). MDT is a low-cost, non-subtractive, patented manufacturing process that mechanically and plastically deforms a workpiece to form finite and repeatable microchannels.

Figure 3. Wolfspeed uses Wieland Microcool’s MDT technology to support 20 chips per inch (FPI) (compared to the standard 12 FPI), resulting in lower thermal resistance and uniform cooling.

This is the basis for a high-performance cold plate with recessed channels that cool the entire contact surface of the XM3 module. The profile of the double-sided CP4012D-XP cold plate is optimized to match the XM3 module specification, and the size is reduced compared to the previous generation CP3012.

Provides even coolant flow to all six module positions at 4 LPM, resulting in a very low thermal resistance of 0.048 °C/W (per position) or 0.008 °C/W (per cold plate). It has been tested that the cooling system consumes up to 750 W per switch when using the CAB450M12XM3.

drive strength

Due to the high power performance of the converter module’s silicon carbide (SiC) MOSFETs, the driver must have a sufficient drive strength (peak output current rating or current value used by the switching device) to maintain fast switching speeds. A rating above 10 A is recommended to ensure high edge rates. Wolfspeed’s CGD12HBXMP gate driver is available.

Figure 4. The XM3 dual-supply core structure supports the use of gate drivers, enhancing stability and simplifying the introduction of thermal paths.

The dual-channel gate driver features overcurrent and reverse polarity protection and an on-board 2 W isolated power supply capable of supporting 80 kHz switching frequency. User-configurable turn-on and turn-off gate resistors reduce switching losses.

The driver also features adjustable overcurrent detection, soft shutdown, undervoltage lockout, and PWM input anti-overlap. It also provides a turn-on-to-off time of about 2 µs for safe shutdown in short-circuit conditions.

Due to the high dV/dt rate of Silicon Carbide (SiC) MOSFETs, insufficient Common Mode Transient Immunity (CMTI) ratings can cause latching between the logic output and driver output, causing hardware failure. The CGD12HBXMP features a high 100 kV/μs CMTI rating, low (

The CGD12HBXMP also has the same size as the XM3 module, enabling the integration of six CAB450M12XM3 modules and their drivers on a cold plate to form a compact power core (Figure 4). This compact solution can be easily integrated into dual inverter designs.

DC link capacitance

Figure 5. Customized DC-Link Capacitor (Left) and Scaled Size Comparison with Six Standard Cylindrical Capacitors

The reduction of parasitic inductance is a key issue, and as mentioned above, the vertically offset power terminal section of the XM3 module reduces parasitic inductance, thereby simplifying busbar design and reducing power loop inductance. This issue is further addressed in the DC link capacitor selection shown in Figure 5.

Capacitance specification is one of the biggest barriers to increasing power density. Typically six off-the-shelf 100 μF cylindrical capacitors are used to achieve the desired ripple current rating, sized at 451 cm2, and require the use of separate bus bars.

Wolfspeed used a specially designed DC link capacitor (Figure 5), measuring only 234 cm2. It features an integrated laminated busbar (connected to the power terminals of the XM3 power modules on both sides of the cold plate), which reduces the parasitic inductance of the power loop and ensures a balanced current path for the two sets of modules. The number of components has also been reduced due to the elimination of separate busbars and hardware.

At 900 V, the custom capacitor is 600 μF and has a peak voltage rating of 1200 V. Capacitance and integrated bus stray inductance are critical to reduce the common voltage spikes at high di/dt rates of fast switching silicon carbide (SiC) inverters, after measuring the 13 nH equivalent series inductance at the terminals with an impedance analyzer , the design has been verified. This capacitor, combined with the XM3 module’s 6.7 nH inductance, results in a total power loop inductance of only 20 nH, enabling faster switching speeds.

controller

When selecting a controller board processor for this system, consider the following:

• There should be sufficient processing “horsepower” to sample all inputs and make control decisions.

● There should be a sufficient number of ADCs to measure all necessary system states for proper control and monitoring.

● There should be a fast hardware interrupt capability for responding to fault conditions.

● Standard communication must be supported, which is critical for proper operation.

Therefore, the system’s controller board uses a dual-core floating-point 200 MHz 32-bit DSP from Texas Instruments. The DSP has ample ADC inputs to measure current, voltage and temperature, and provides communication support (including isolated CAN).

current sensor

Dual inverters use six current sensors at the output terminals. Due to the large number of sensors in the system, even a small reduction in the size of the sensor module chosen can have an immediate and significant impact. While COTS current sensor modules are readily available, they can be bulky. Additionally, some 3-in-1 sensor modules on the market impose more constraints on the busbar geometry.

For the CRD600DA12E-XM3 system, Wolfspeed chose a DC to 250 kHz Melexis MLX91208 Hall-effect sensor that provides a high-speed analog output signal proportional to the external horizontal magnetic flux density with a response time as low as 3 µs.

Housed in an eight-pin SOIC package, the sensor is small enough to mount on a compact PCB and connect directly to the output bus. PCB mounting flexibility allows for simplified output busbars.

In addition, the MLX91208 uses an Integrated Magnetic Concentrator (IMC) deposited on a CMOS chip, eliminating the need for a larger ferromagnetic core (Figure 6). The assembly size is 91.6 mL, while another common sensor assembly in the automotive industry has a volume of 800 mL.

Figure 6. The Melexis IMC Hall sensor avoids the use of bulky ferromagnetic cores and can be significantly reduced in size.

The high dV/dt rates typically found in silicon carbide (SiC) inverters can create noise on low voltage sensitive signals such as those of current sensors. The current sensor is very close to the joint, making it more susceptible. The same goes for the cables between the sensor and the controller, and the wiring around the system also picks up noise.

The sensor selected by Wolfspeed requires only a stacked U-shaped magnetic screen to prevent external field interference and to homogenize the magnetic field. The ground plane of the PCB prevents capacitive coupling of the busbar to the sensor. The use of differential signaling significantly reduces the effects of switching radiated noise. In addition, the use of shielded twisted pair CAT6 cable between the sensor board and the controller ensures that the noise of a pair of differential signals is common mode noise.

Test performance

Double-pulse testing of clamped inductive loads with low gate resistance under harsh switching conditions verifies the entire power loop. The constant current load waveform shows a turn-on switching energy of 23.1 mJ and a peak current overshoot of 113 A at 800 V and 600 A.

The turn-off switching energy is 30.1 mJ. The chip has a bus voltage margin of 80 V, which is a 2x overload condition compared to the module’s nominal rating.

Next, the switching losses for each module were calculated based on the known turn-on energy of 12.2 mJ and turn-off energy of 12 mJ at 300 A nominal. Using switching power loss (PSW)formula,

and insert EON and a switching frequency of 10 kHz (fSW),

Silicon carbide (SiC) has the huge advantage of extremely low reverse recovery energy (ERR), which is 3 times lower losses than comparable Si IGBTs (HybridPack 1200 V, 380 A nominal).

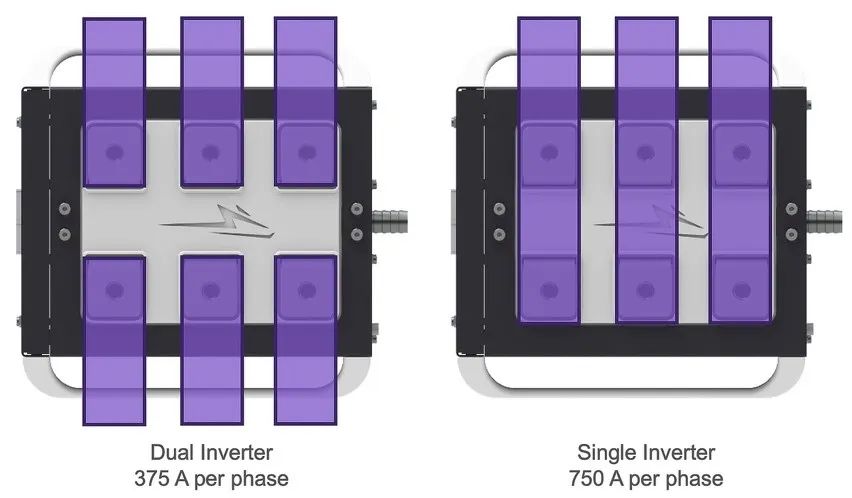

Figure 7. The output bus arrangement provides flexibility to support applications requiring higher current output from a single inverter.

The design was also verified under application conditions by three-phase recirculation load testing.

The flexible arrangement of output terminals in this design simplifies test setup—six outputs can be used as two independent three-phase inverters, each with 375 ARMS, or by adding simple bus bars and parallel phases, as A single three-phase inverter capable of 750 ARMS (Figure 7).

The test used a single inverter setup, with the AC outputs U and X combined to form phase A, V and Y to form B phase, and W and Z to form C phase. Three 125 µH load inductors are connected between one of the output terminals of the inverter and the midpoint of the large capacitor bank (2.2 mF per half), rated at 1100 V.

This allows high power tests to be performed with only a few kilowatts of power, with only system losses in the DC voltage supply. During each switching cycle, energy is transferred from one half of the capacitance to the other half through the Inductor, and the direction of energy transfer flips during one fundamental frequency cycle.

Tested for five minutes at a bus voltage of 800 V, the capacitor case temperature was 13°C higher than ambient, and the gate driver hotspot was measured 40°C higher than ambient. For a switching frequency of 10 kHz and a fundamental frequency of 300 Hz, the RMS parallel output current is 750 A, which corresponds to an output power of 624 kW. At 10 kHz, the selected load inductor has a current ripple of 160 A and a peak combined current of 1200 A (including current ripple).

Figure 8. Inverter power loss (left) and efficiency (right) at 800 V, 10 kHz, 25 °C coolant

The switching energy at 10 kHz, 375 A is 31 mJ. For a total loss of 5.53 kW or 460 W per switch, the switching losses are 1.8 kW. As a result, inverters up to 624 kW are more than 99% efficient (Figure 8).

Summarize

The CRD600DA12E-XM3 three-phase dual-inverter reference design meets the five key design factors described above, utilizing the CAB450M12XM3 power module to achieve a peak output power of 624 kW and a current rating of 375 Arms per phase or 750 Arms in parallel.

Table 1. The CRD600DA12E-XM3 achieves a power density of 72.5 kW/L, which is 3.6 times higher than the potential value of an equivalent rated IGBT design.

This solution uses an all-metal housing of 204 × 267.5 × 157.5 mm (as shown in Figure 1), weighs 9.7 kg, and has a volume of only 8.6 L, which can achieve an ultra-high power density of 72.5 kW/L, which is higher than the previous 300 The kW silicon carbide (SiC) reference design is more than twice as high and 3.6 times higher than the potential of an equivalent rated IGBT inverter (Table 1).

For more information on the CRD600DA12E-XM3 three-phase dual inverter reference design, CAB450M12XM3 power module and CGD12HBXMP gate driver, please contact the Wolfspeed team.

For English manuscripts, please visit:

https://www.wolfspeed.com/knowledge-center/article/silicon-carbide-modules-unlock-higher-power-density-in-motor-drives

Source: Wolfspeed